top of page

HOME / RESOURCES

Expert Insights on Mechanical Seals, Pumps and More

Technical articles, product updates, and case studies

At Specialised Flow Solutions, we are committed to providing our customers with the most relevant and helpful information to keep your mechanical seals, pumps, and rotating equipment running smoothly. Our technical articles cover topics ranging from product updates to preventative maintenance tips, aimed at extending the life of your critical assets. Stay ahead of the industry trends and equip yourself with the latest knowledge from our team of experts.

Have a question? We're here to help.

Search

HOW FLEXASEAL SOLVED CRYOGENIC SEAL CHALLENGE

A leading cryogenic gas manufacturer needed a sealing solution that could survive temperatures as low as -425°F. Their existing design failed too often, driving up maintenance costs. Flexaseal’s engineered cryogenic mechanical seal — featuring a 347 stainless steel welded bellows and cryogenic-grade materials — delivered reliable, long lasting performance. Learn how this proven cryogenic seal improved MTBF, reduced downtime, and set a new standard for cryogenic sealing.

THE LINK BETWEEN MECHANICAL SEALS AND SUSTAINABILITY

Mechanical seals and sustainability go hand in hand. These critical sealing devices prevent leaks, reduce product loss, and maximise efficiency. With over 40 years’ combined experience, Specialised Flow Solutions delivers fast, flexible, and customised sealing solutions—keeping industries leak-free, compliant, and environmentally responsible.

MECHANICAL SEAL INSTALLATION AND MAINTENANCE BEST PRACTICES

When it comes to mechanical seals, getting the installation right and sticking to good maintenance habits can make all the difference. A well-installed, properly maintained seal can significantly boost reliability, reduce the risk of failure, and save you from unnecessary downtime and repair costs. Need help or mechanical seal repairs? Our Gladstone, QLD team supports all major brands with fast turnaround. Contact us today.

FLEXASEAL MECHANICAL SEALS: INDUSTRIES AND APPLICATIONS

Flexaseal’s mechanical seals are trusted in Oil & Gas, Chemical, Pulp & Paper, Power, Pharma, and Water Treatment industries. From double seals for sour service to hygienic designs with TGA-approved materials, Flexaseal delivers performance and reliability. As Flexaseal’s exclusive Australian distributor, Specialised Flow Solutions provides expert support to match the right seal to your application.

THE EVOLUTION OF FLEXASEAL: A WORLD LEADER IN MECHANICAL SEAL INNOVATION

From its visionary beginnings to industry leadership, Flexaseal's journey reflects a commitment to excellence and innovation. With a focus on meeting evolving global needs, Flexaseal continues to drive progress in mechanical seal technology—delivering cutting-edge solutions for the future.

ROCK KILLER CRUSHER (RKC) SERIES: HEAVY-DUTY FLUSHLESS SLURRY PUMP SEAL SOLUTIONS

The Rock Killer Crusher (RKC) Series sets a new benchmark in flushless slurry pump seal technology. Designed for the harshest applications in mining and industry, the RKC Series delivers reliable, efficient sealing without external flush systems. With four configurable options and abrasion-resistant materials, it offers long-lasting performance, reduced maintenance, and proven success in high-solids environments. Available in Australia exclusively from Specialised Flow Soluti

FLEXASEAL MLC3: ADVANCED MULTI-LIP CARTRIDGE MECHANICAL SEAL FOR VISCOUS AND HARSH APPLICATIONS

Viscous fluids like syrups, resins, and adhesives can overwhelm traditional seals—but not the Flexaseal MLC3. This modular triple lip cartridge seal handles thick, sticky media with ease, achieving reliable sealing at lower speeds without the need for complex seal support systems. Ideal for pumps, mixers, and agitators, the MLC3 delivers exceptional performance in high-viscosity, slow-moving, and demanding applications across multiple industries.

MECHANICAL SEAL VAPOUR PRESSURE CONTROL USING API PIPING PLANS

Controlling vapour pressure in mechanical seal chambers is critical to avoiding flashing and seal failure. API piping plans like Plan 11 and Plan 14 help maintain seal face stability without a heat exchanger by increasing seal chamber pressure and removing heat. Learn how to improve seal reliability using pressure-driven flush plans with help from Specialised Flow Solutions.

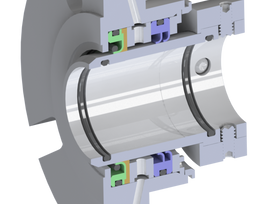

COMPARISON GUIDE: EDGE WELDED METAL BELLOWS vs FORMED BELLOWS

There are two main classifications of metal bellow seals: edge welded metal bellows an formed bellows. Here we discuss the advantages and...

SELECTING MECHANICAL SEALS FOR MIXERS AND AGITATORS

The Flexaseal Style 85M Split Cartridge Mechanical Seal is engineered specifically for mixers and agitators, offering a reliable sealing solution without the need for equipment disassembly. Its innovative split design simplifies installation and maintenance, reducing downtime and labor costs. Built for challenging applications, the 85M delivers durability, performance, and efficiency where it matters most.

HOW TO STORE A MECHANICAL SEAL SAFELY WITHOUT COMPROMISING FUNCTION

Mechanical seals are made from a range of materials like steel, rubber, silicon, carbon, and PTFE. Their precise design makes proper storage essential to maintain performance. When stored correctly in a clean, temperature and humidity-controlled environment, mechanical seals can typically be kept safely for up to five years without compromising their integrity.

KEY CONSIDERATIONS WHEN SELECTING A MECHANICAL SEAL

Failure to select the proper mechanical seal type can lead to loss of pump integrity, breakdowns and costly repairs.

TROUBLE SHOOT MECHANICAL SEAL ISSUES

What are your mechanical seal faces showing you? Heat checking? Coking? Blistering? Understand the causes and troubleshoot these issues.

HOW TO CHANGE MECHANICAL PACKING TO A SPLIT CARTRIDGE MECHANICAL SEAL

While braided packing can be a solution for many services, its upkeep requirements often force operators to consider mechanical seals.

PROS AND CONS OF DIFFERENT TYPES OF MECHANICAL SEALS FOR CENTRIFUGAL PUMPS

This article highlights the pros and cons of the different types of mechanical seals and key considerations when selecting a mechanical seal

CHOOSING THE RIGHT SPLIT CARTRIDGE MECHANICAL SEAL

A Split Cartridge Mechanical Seal is an innovative sealing solution for environments where it may be difficult to install or replace conventional mechanical seal

INTRODUCTION TO EDGE-WELDED METAL BELLOWS SEALS

Edge-welded metal bellows are flexible, high-performance mechanical seals ideal for harsh, high-temperature, and cryogenic applications. Offering precise spring rates, superior flexibility, and long-lasting reliability, these edge-welded bellows outperform formed and pusher-type seals in industries from oil & gas to food processing. Learn how their design, materials, and construction deliver dependable sealing in demanding conditions.

4 COMMON REASONS FOR MECHANICAL SEAL FAILURE

Mechanical seals are a common pain-point in pumping applications, here are the four most common reasons for failure.

SIMPLIFYING MECHANICAL SEAL INSTALLATIONS WITH FLEXASEAL'S SPLIT CARTRIDGE SOLUTION

Flexaseal's Style 85 Split Cartridge Seal is designed to reduce downtime for challenging and time consuming installations.

bottom of page